It’s one of countless Cybertruck prototypes we’ve seen this year

Source: Electric Vehicle News

Electric Vehicle News

State Bicycle Co. 4130 “Acoustic” — CleanTechnica Tested

Consider this the first episode of “E-bikes Unplugged” from CleanTechnica.

Source: CleanTechnica Car Reviews RSS Feed

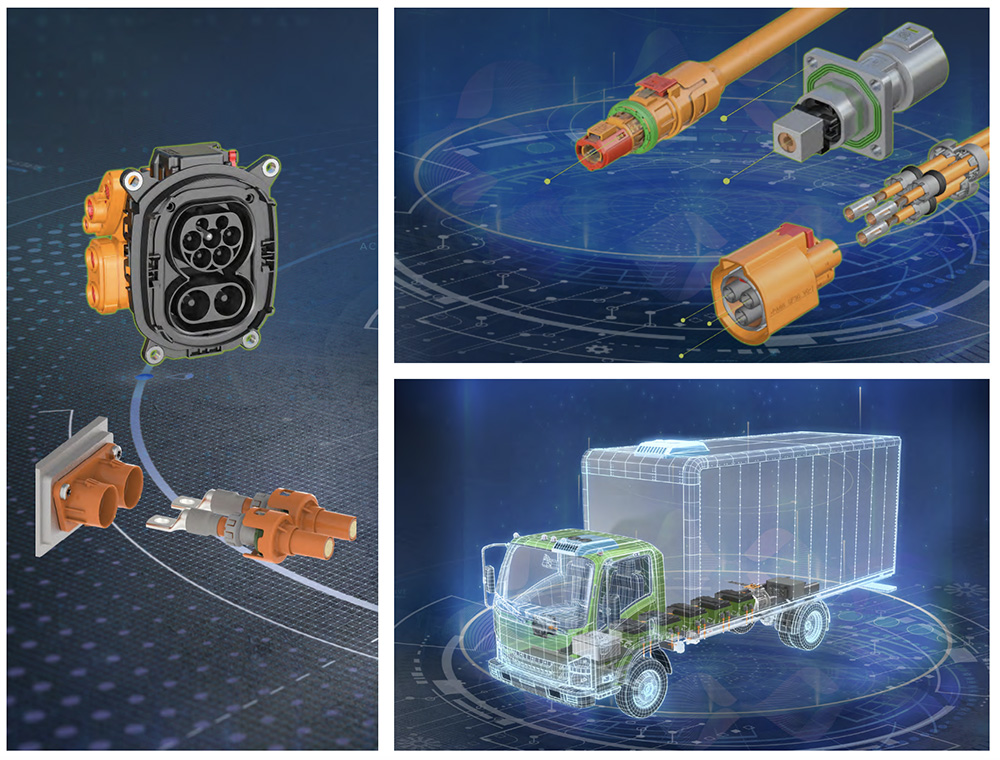

TE Connectivity develops HIVONEX connector and PowerTube charging solutions for EVs

TE Connectivity, a connectivity and sensor manufacturer, has developed connector and charging solutions for the EV transition.

The HIVONEX range offers modular, scalable products for harsh industrial and commercial vehicle settings and includes the new PowerTube Connector Series for large electrical loads such as those in trucks, buses, and construction and agricultural vehicles. Other products in the portfolio include:

- IPT-HD Power Bolt Connector: a bolted solution for the motor control unit (MCU), e-axle and e-motor applications. The connector can withstand extreme temperatures and engine-level vibrations and offers a new shielding design to improve electromagnetic compatibility (EMC) performance. It supports up to three positions: 50, 70, and 95 mm² wire size; and pre-made wire harnesses.

- ICT Charging Inlets: available in kits and pigtail cable assemblies.

- HVA HD400 Connector: developed for high-voltage accessory vehicle applications such as HVAC, heaters, hydraulic pumps and electronic power steering. This solution is capable of withstanding extreme temperatures (-40° C to +140° C) and transmission-level vibrations, meets IP68/IP6K9K ratings, and allows two or three conductors in the same interface.

“The HIVONEX connector and charging products are designed for extreme environments—safe connectivity, scalability and high voltages of power for those operating in the field,” said Sebastien Dupre, Director of Product Management for the E-mobility Product Portfolio at TE.

Source: TE Connectivity

Source: Electric Vehicles Magazine

Enevate teams with Korea’s JR to build a battery electrode manufacturing facility in the US

Korean battery firms are hooking up with US companies to get in on the stateside EV battery gold rush. The latest partnership to be announced is between US-based Enevate and South Korea’s JR Energy Solution (JR ES).

JR ES boasts a unique electrode and battery cell foundry model that enables cell manufacturers to produce tailor-made electrodes and cells. The company recently broke ground on its first production facility in South Korea, which is to start production in Q4 of this year.

Enevate recently licensed its silicon-dominant XFC-Energy battery technology to JR ES. The collaboration will now be expanded to include the joint construction of an electrode manufacturing facility in the US. The companies have signed a letter of intent, and are scouting potential locations. The eventual capacity is expected to be 6 GWh anodes and 6 GWh cathodes per year.

The facility will produce tailor-made anodes and cathodes for Enevate customers. The facility will also provide various electrode solutions for other customers including graphite, silicon, LFP, NMC, NCMA and NCA, for different battery cell form factors such as pouch and cylindrical cells.

Customers will have the opportunity to develop electrodes and battery cells using Enevate’s XFC-Energy technology, which the company says delivers up to 10 times faster charging than conventional lithium-ion batteries, as well as improved cold-weather performance.

“This collaboration with JR Energy Solution is great news for the whole battery industry in the US,” said Enevate CEO Bob Kruse. “It will allow customers to get access to Enevate’s silicon-dominant battery technology and to tap into JR ES’s knowledge and expertise in electrode and battery cell manufacturing. Moreover, it will enable customers to accelerate their development process or to outsource parts of their production capacity.”

“This is a huge milestone for JR ES to bring our unique expertise in electrode development and manufacturing to the US,” said JR Energy Solution CEO Duke Oh. “It will also allow us to expand our electrode foundry model to the US and to serve US- based customers even better.”

Source: Enevate

Source: Electric Vehicles Magazine

Ampcontrol raises $10 million in financing for EV fleet charging software

US-headquartered Ampcontrol has secured $10 million in Series A financing from The Westly Group, along with existing investors AngelPad and Lorimer Ventures. Ampcontrol will use the funds to continue development of its AI-powered charging platform designed to reduce energy costs and EV charger downtime.

The company says more than 20 fleet operators, including WattEV, First Bus and Revel, as well as a large global truck manufacturer, are using the platform in the US, Europe, Latin America and Africa.

The software makes real-time decisions and provides detailed monitoring tools, dynamic load management, V2G integrations and telematics integrations with partners such as Geotab.

Source: Ampcontrol

Source: Electric Vehicles Magazine

Advertising watchdog bans Toyota and Hyundai EV ads over charging time claims

Seemingly every press release about an EV or charging station includes a claim about charging time. “It can charge from X to X% in X minutes…” This is understandable, because it’s the first thing most potential EV buyers ask about (once they become actual EV owners, the fixation on charging time tends to fade). However, charging speed depends on so many factors (the EV model, its state of charge at the time, the battery age and condition, even the local weather) that these figures are next to meaningless. Furthermore, like range figures, charging speed figures may be based on laboratory tests that don’t reflect real-world driving conditions.

In the UK, a couple of ad campaigns by Toyota and Hyundai have fallen afoul of the Advertising Standards Authority, an advertising industry watchdog, for exaggerating the speed at which their EVs can be charged, and misleading consumers about the availability of fast charging stations in the UK and Ireland.

Toyota ran a marketing campaign on its web site for its bZ4X, which claimed the vehicle could be charged to 80% in about 30 minutes with a 150 kW DC fast charger. Toyota also said drivers could “easily find rapid-charging points in a number of public locations,” especially in areas where “drivers were most likely to need them.”

Hyundai ran a similar campaign for its Ioniq 5, claiming that the EV could be charged from 10% to 80% in 18 minutes using a 350 kW charger.

The Guardian reports that the Advertising Standards Authority received complaints challenging the charging time claims. Both companies admitted that these were measured in ideal factory conditions, and the ASA questioned whether they were achievable in the real world. The claims about the availability of DC fast charging points in the UK were also challenged.

Toyota said that at the time it ran the ad campaign, the UK web site Zap-Map showed that there were 150 kW charging points at 134 locations across the UK. However, there were just 7 in Scotland, 2 in Wales and none in Northern Ireland. The Charge myHyundai web site showed that there were 37 350 kW charging locations in Great Britain, 6 in the Republic of Ireland, “limited numbers” in Wales and Scotland, and none in Northern Ireland.

The ASA said the manufacturers had given the impression it was “relatively straightforward” to access high-power chargers across the UK. The watchdog also noted the numerous factors that affect charging times in the real world. “If any of those conditions were less than optimal, then charging times would likely take longer,” the ASA correctly pointed out.

Despite the automakers’ protests that they need to advertise fast charging times in order to address one of the main obstacles to EV adoption, the ASA banned the ad campaigns, and told Toyota and Hyundai not to mislead consumers about battery charging times in future.

This is reportedly the first time the UK’s ASA has addressed marketing claims for any EV. However, Toyota’s Lexus brand has been criticized many times in the past for misleading ads concerning EVs. In 2020, Norway’s Consumer Authority found a Lexus ad for a “self-charging hybrid” (essentially a perpetual motion machine) to be deceptive, and in violation of the country’s Marketing Act.

Source: The Guardian

Source: Electric Vehicles Magazine

Ford F-150 Lightning Production Resumes: Annual Run Rate At 150,000

Six weeks of retooling at the Rouge plant has led to much-improved production capacity.

Source: Electric Vehicle News

California Cops Cracking Down On Illegal Electric Bikes

Cops in Newport Beach are taking to the streets on horseback to catch offenders riding high-power e-bikes not legal for street use.

Source: Electric Vehicle News

Tesla Model Y Fails To Meet Range Claims Year Round: Consumer Reports

Rival EVs also suffer during cold weather, but the American crossover falls short of estimates even when it’s warm outside.

Source: Electric Vehicle News

First Chrysler EV Will Drop Airflow Name, Be Previewed By New Concept

Set to be unveiled next year, the new concept is so different that it doesn’t even use the Airflow name.

Source: Electric Vehicle News