Hybrid systems aren’t all tuned for the highest possible fuel efficiency. You can use the boost of an electric motor system to actually increase the capability of a vehicle without using more fuel—which in turn saves fuel as you don’t have to opt for a bigger vehicle or bigger engine. Such is the case with the hybrid system Ford…

Hybrid systems aren’t all tuned for the highest possible fuel efficiency. You can use the boost of an electric motor system to actually increase the capability of a vehicle without using more fuel—which in turn saves fuel as you don’t have to opt for a bigger vehicle or bigger engine. Such is the case with the hybrid system Ford…

Source: Hybrid and Electric Car News and Reviews

Porsche CEO: EVs are the future, but they won't completely replace combustion engines

The Volkswagen Group has made one of the largest investments in electric-car building, infrastructure, and development for any automaker on the planet. In the next decade, Volkswagen and its subsidiaries including Audi, Porsche, and others, plan on building millions of EVs and will invest billions more into charging infrastructure. In an Op-Ed…

The Volkswagen Group has made one of the largest investments in electric-car building, infrastructure, and development for any automaker on the planet. In the next decade, Volkswagen and its subsidiaries including Audi, Porsche, and others, plan on building millions of EVs and will invest billions more into charging infrastructure. In an Op-Ed…

Source: Hybrid and Electric Car News and Reviews

Fraunhofer’s dry coating process for electrodes could make cell production in Europe economical

Researchers at Germany’s Fraunhofer Institute for Material

and Beam Technology IWS have developed a new battery cell production process

that coats electrodes with a dry film instead of liquid chemicals. This

simplified process saves energy and eliminates toxic solvents. The Fraunhofer researchers,

with colleagues from Samsung, describe their findings in a new paper, “Overcoming binder

limitations of sheet-type solid-state cathodes using a solvent-free dry-film approach,” published

in Energy Storage Materials.

Maxwell Technologies, now a subsidiary of Tesla, is also working

on a

dry electrode tech that eliminates the need for toxic solvents. Once Tesla and

partner Panasonic get Maxwell’s process up and running, it’s expected to save

loads of money, time and factory space.

Reducing the costs of producing battery cells is a highly

desirable end in itslef, but the Fraunhofer engineers see the potential to

change the global energy storage market. For years, Asian companies have

dominated the battery cell market. German (and US) automakers currently get

most of their cells from Korean and Japanese companies. As the proliferation of

EVs and stationary storage applications increases demand for cells, this is

becoming an increasingly intolerable situation. That’s why, last November, the

German government announced that it would invest a billion euros to support

local battery cell production (as reported by Reuters

via Electrek).

One reason the Asians dominate the cell market is a cost

advantage – the current process for producing cells is very energy-intensive,

and Germany has famously high electricity prices. A lower-cost production

method could change the equation.

“Our dry transfer coating process aims to noticeably reduce

the process costs in electrode coating,” said paper co-author Dr. Benjamin

Schumm. “Manufacturers can eliminate toxic and expensive solvents and save

energy costs during drying. Our technology also facilitates the use of

electrode materials that are difficult or even impossible to process

wet-chemically. For all these reasons, we think that our technology can help to

achieve internationally competitive battery cell production in Germany and

Europe.”

The current wet-chemical process involves mixing the active battery

materials with additives to create a paste, adding expensive organic solvents. Elaborate

precautions are necessary to protect workers and the environment from the toxic

solvents. Once the paste has been applied to thin metal foils, dozens of large

heating elements are used to dry the coated films – this drying procedure is

what racks up the high electricity costs.

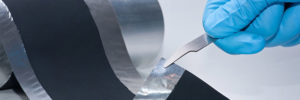

The new film transfer technology eliminates these steps. The

IWS engineers mix their active material with binding polymers, then process

this dry mixture in a rolling mill, where shear forces tear molecular chains

out of the binder polymers. These fibrils join with the electrode particles to

form a web that provides the electrode material with stability. The result is a

flexible dry electrode material layer. In the next step, the rolling mill

laminates the 100-micrometer-thick film onto an aluminum foil to form the finished

electrode.

The Finnish company BroadBit Batteries is working with Fraunhofer to commercialize the new process. The firm has commissioned a pilot plant in its Espoo factory, which will use the dry coating process to produce new types of sodium-ion batteries.

Source: Fraunhofer Institute via Green Car Congress

Source: Electric Vehicles Magazine

Honda E electric car: 50/50 weight distribution, “in action” tease next month

Honda’s sporty, retro-cute Urban EV Concept created quite a buzz ever since its 2017 Frankfurt Motor Show debut. And now, with the Honda E, as it will be called, fast-tracked and due to be shown in production form later this year, Honda is aiming to keep up the excitement. This week, Honda revealed some key details about the production…

Honda’s sporty, retro-cute Urban EV Concept created quite a buzz ever since its 2017 Frankfurt Motor Show debut. And now, with the Honda E, as it will be called, fast-tracked and due to be shown in production form later this year, Honda is aiming to keep up the excitement. This week, Honda revealed some key details about the production…

Source: Hybrid and Electric Car News and Reviews

Subaru and Toyota plan joint electric SUVs on flexible platform

What comes next after a partnership for sports cars? Potentially one for an electric SUV. That’s the latest plan from Toyota and Subaru, according to a joint statement from the automakers on Thursday. The new joint project will develop a new electric mid-size SUV using electric-car technology from Toyota and all-wheel drive technology from Subaru…

What comes next after a partnership for sports cars? Potentially one for an electric SUV. That’s the latest plan from Toyota and Subaru, according to a joint statement from the automakers on Thursday. The new joint project will develop a new electric mid-size SUV using electric-car technology from Toyota and all-wheel drive technology from Subaru…

Source: Hybrid and Electric Car News and Reviews

Tesla gets (more) real with online pricing, downplays gas-price game

It came as something of a breakthrough on Monday when Tesla updated its website to, nearly, put cash prices for its cars up front in its Design Studio—where potential buyers go to configure the cars they want to buy. Until now, shoppers had to complete building their cars online to see the final price. Up to that point, Tesla only showed an…

It came as something of a breakthrough on Monday when Tesla updated its website to, nearly, put cash prices for its cars up front in its Design Studio—where potential buyers go to configure the cars they want to buy. Until now, shoppers had to complete building their cars online to see the final price. Up to that point, Tesla only showed an…

Source: Hybrid and Electric Car News and Reviews

Watch Tesla Model X Charge Using CCS Combo 2 Adapter At 130 kW

The new Tesla CCS Combo 2 adapter can provide up to roughly 130 kW of charging power, according to a test of new Model X 100D.

Source: Electric Vehicle News

Hyundai Kona Hybrid announced for Europe, not confirmed for US

Hyundai announced on Monday that it will introduce a new hybrid version of its Kona small SUV in Europe. The model follows the standard Kona and the Kona Electric, which went on sale in Europe last year and in the U.S. this spring. The Kona Hybrid uses Hyundai’s standard hybrid system with an electric motor built into the six-speed dual-clutch…

Hyundai announced on Monday that it will introduce a new hybrid version of its Kona small SUV in Europe. The model follows the standard Kona and the Kona Electric, which went on sale in Europe last year and in the U.S. this spring. The Kona Hybrid uses Hyundai’s standard hybrid system with an electric motor built into the six-speed dual-clutch…

Source: Hybrid and Electric Car News and Reviews

$50 billion VW battery plan could need revamp after Samsung cuts back

Volkswagen, with its plan to build 22 million new electric cars across 70 models by 2030, is ground-zero for concerns over battery supplies. As more automakers get serious about building lots of electric cars, there are indications that supplies of batteries to power all those cars aren’t ramping up as quickly, leading to shortages of batteries…

Volkswagen, with its plan to build 22 million new electric cars across 70 models by 2030, is ground-zero for concerns over battery supplies. As more automakers get serious about building lots of electric cars, there are indications that supplies of batteries to power all those cars aren’t ramping up as quickly, leading to shortages of batteries…

Source: Hybrid and Electric Car News and Reviews

Fiat Chrysler submits offer for Renault merger, could jump-start electric car development

Fiat Chrysler Automobiles proposed a merger Monday with French automaker Renault that would result in one of the world’s largest automakers by volume and create one of the most diverse. The wide-ranging, multi-billion-dollar bid was submitted Monday by FCA after a furious weekend of negotiations that may have started off as an exploration of loose…

Fiat Chrysler Automobiles proposed a merger Monday with French automaker Renault that would result in one of the world’s largest automakers by volume and create one of the most diverse. The wide-ranging, multi-billion-dollar bid was submitted Monday by FCA after a furious weekend of negotiations that may have started off as an exploration of loose…

Source: Hybrid and Electric Car News and Reviews