New designs for power converters demand compact, high power density components and are increasingly using higher switching frequencies. This has become a real challenge for magnetic component designers to overcome the extra losses created by large air gaps necessary for transformers and resonant inductors, those related to fringing effect.

Join this webinar at next week’s Virtual Conference on EV Engineering, presented by Prax Power, where we will introduce key rules and considerations for the design of such transformers and resonant inductors.

Multi-gap technology has been developed by PRAX to reduce winding AC losses. It allows a large air gap to be evenly distributed on a toroid to minimize fringing effect by splitting the gap into smaller gaps.

The use of multigap (XGAP TM) technology allows for the creation of cost-effective solutions with maximum power density thanks to the reduction of core volume around 30%, while overall size reductions up to 20%. Mutigap technology also minimizes losses and offers optimal heat dissipation of windings in all type of cooling systems. All of these advantages match the requirements of magnetic components in EV charging applications.

Other sessions at our Spring Virtual Conference include:

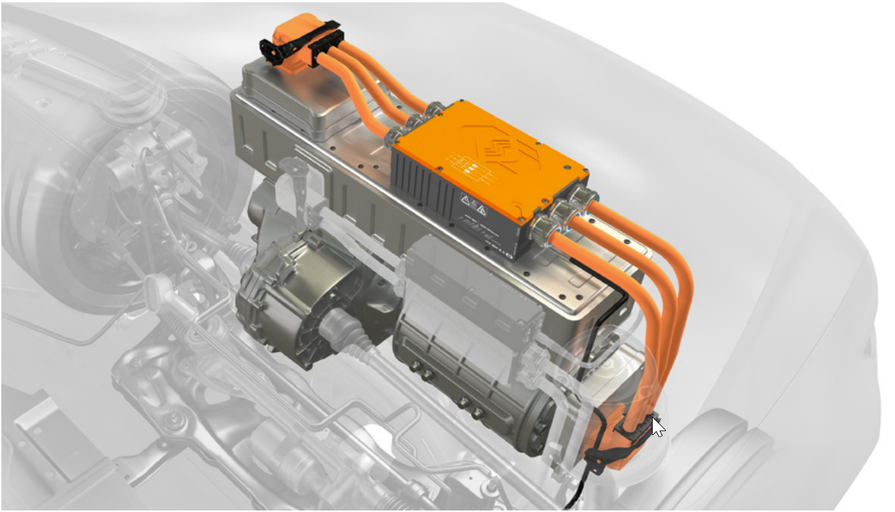

Power And Efficiency Measurements Of Electrified Vehicles

This presentation, presented by CSM, will introduce both an overview and the latest updates to the world-leading measurement hardware and software for power and efficiency measurement of inverters and electric motors. Attendees will learn the foundation and unique benefits of the Vector-CSM eMobility Measurement System which provides for the use of consistent tools throughout your product development cycle.

See the full session list for the Spring Virtual Conference on EV Engineering here.

Broadcast live April 17 – 20, 2023, the conference content will span the EV engineering supply chain and ecosystem, including motor and power electronics design and manufacturing, cell development, battery systems, testing, powertrains, thermal management, circuit protection, wire and cable, EMI/EMC and more.

Source: Electric Vehicles Magazine