The concept will debut in January at the CES 2023, marking a return for Peugeot to America since the brand is not coming back to the US.

Source: Electric Vehicle News

Electric Vehicle News

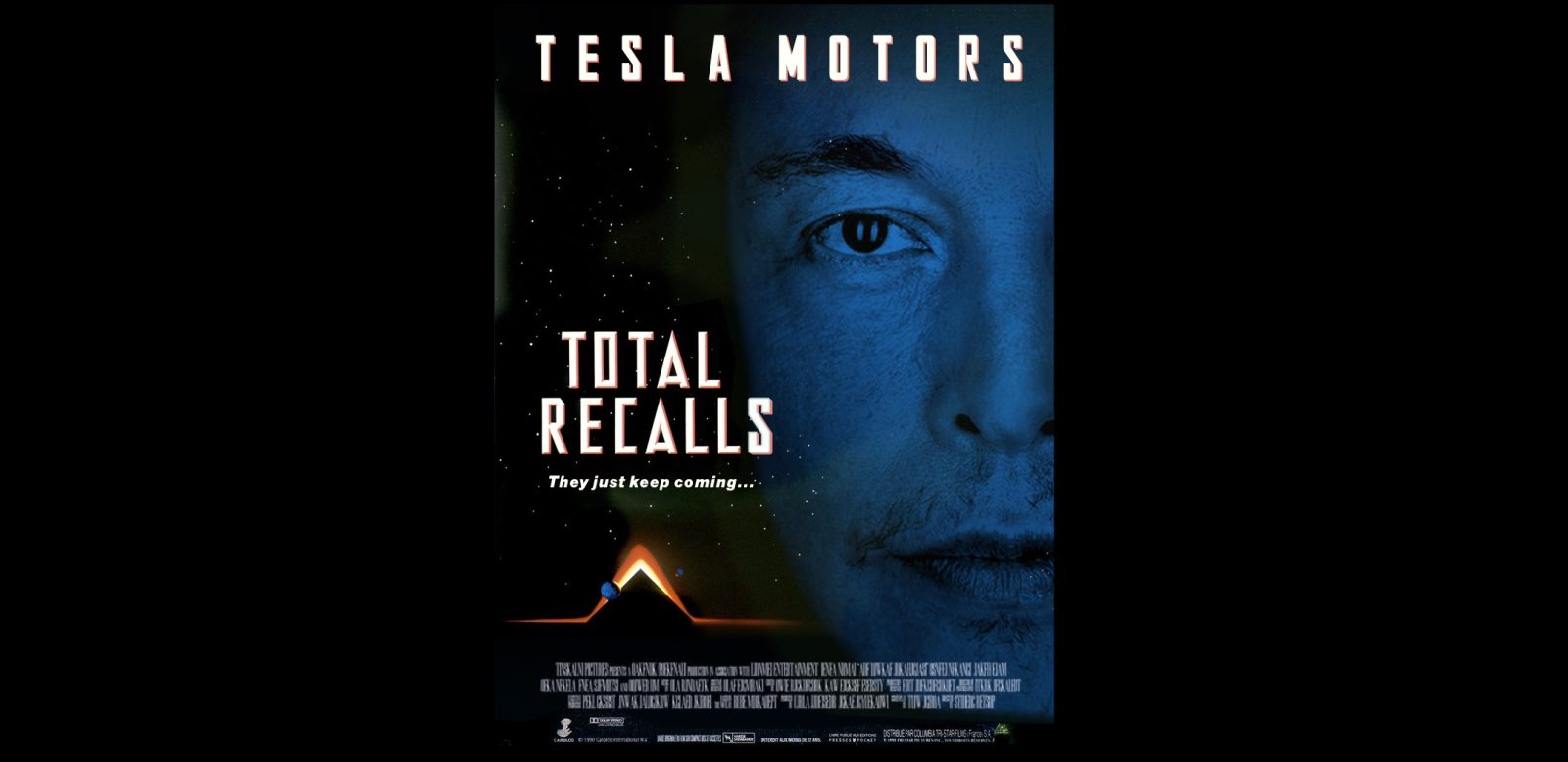

Tesla adds another recall to a ‘Total Recall’ year

Tesla issues a recall on 80,000 cars in China adding another one to a year with a lot of recalls, but most of them are easily fixed with software updates.

The post Tesla adds another recall to a ‘Total Recall’ year appeared first on Electrek.

Source: Charge Forward

Top EVs LA Auto Show, Pizza, Mazda & Hyundai: EV News Nov. 25, 2022

There’s nothing like Black Friday for a healthy helping of compelling EV news to share with family and friends.

Source: Electric Vehicle News

J+ Booster 2 EV Charger Review

We freeze, submerge and run over the rugged J+ Booster 2 to find out if it’s as tough as advertised.

Source: Electric Vehicle News

MG ZS EV vs. BYD Atto 3 — Dual Owner Comparison!

As the battle between MG and BYD for the title of second highest selling electric vehicle in Australia heats up, I met with a couple that own one of each. Tired of waiting for the BYD Atto 3 to arrive, they purchased an MG ZS EV 18 months ago and are well placed to compare […]

As the battle between MG and BYD for the title of second highest selling electric vehicle in Australia heats up, I met with a couple that own one of each. Tired of waiting for the BYD Atto 3 to arrive, they purchased an MG ZS EV 18 months ago and are well placed to compare […]

Source: CleanTechnica Car Reviews RSS Feed

Vinfast achieves milestone with first batch of VF8 EVs shipped to the US

Vietnamese electric vehicle maker Vinfast hit a major milestone Friday, shipping the first batch of VF8 SUVs to the US.

The post Vinfast achieves milestone with first batch of VF8 EVs shipped to the US appeared first on Electrek.

Source: Charge Forward

Electrify America invests $3 million in California to promote EVs in disadvantaged communities

Electrify America has announced nearly $3 million in new investment to help four community-based organizations to promote zero-emission vehicle education and awareness in low-income and disadvantaged communities throughout California. This effort is part of the company’s existing plan to invest $200 million in California ZEV infrastructure and education programs through mid-2024.

Through 2021, EA has invested $197.3 million in low-income, disadvantaged and underserved California communities to promote ZEV driving, including $18 million in education and marketing.

The new investment will support digital and in-person education, EV ride-and-drive events, EV incentive and financing workshops, and home charging education.

More than 100 California organizations were invited to submit proposals to support brand-neutral ZEV education and awareness. Investment recipients include:

Breathe SoCal, which will host EV educational sessions for ride-share drivers, a ride-and-drive EV event, and a miniature EV competition for families, all in and around the Long Beach-Wilmington area;

Ecology Action, which will host ride and-drive-events, EV showcases, EV purchase support guidance and EV webinars throughout the Central Coast;

Plug In America, which will organize ride-and-drive programs across California and EV test drives in rural communities;

Valley Clean Air Now, which is committed to reducing air pollution in the San Joaquin Valley, a region with some of the worst air quality and most severe poverty in the US. VCAN and partners such as Charge Across Town will offer disadvantaged community groups test drives and help with qualifying for ZEV incentives. VCAN will also recruit new car dealers to join the Clean Cars 4 All program.

Source: Electrify America

Source: Electric Vehicles Magazine

Mercedes-Benz introduces electric EQE Sedan

The upcoming EQE Sedan is an electric version of the Mercedes-Benz E-Class. It’s based on the Mercedes-EQ electric architecture (EVA2). The 2023 model is scheduled to arrive in US dealerships in the fall, at a starting price of $74,900.

All EQE models have an electric drivetrain (eATS) on the rear axle. The 2023 lineup includes the entry-level EQE 350 and the performance EQE 350+, as well as the EQE 350 and 500 4MATIC dual-motor AWD versions.

Fitted with a 90.6 kWh battery, the EQE 350+ delivers 305 miles of range, according to EPA estimates. The batteries were developed at the Mercedes-Benz Battery Competence Center and are produced at the company’s Stuttgart-Untertürkheim plant.

The EQE’s battery pack contains ten modules. The active material consists of nickel, cobalt and manganese in a ratio of 8:1:1. This reduces the cobalt content to less than 10%. Mercedes hopes to be able to dispense entirely with materials such as cobalt through the use of new post-lithium-ion technologies.

An EQ-specific navigation system called Electric Intelligence factors the elements of electric driving, such as available charge, charging stations along the route, and driving style, into its route calculations, and computes the energy demand of the route.

Source: Mercedes-Benz

Source: Electric Vehicles Magazine

Nouveau Monde Graphite, Panasonic and Mitsui to develop graphite project in Québec

Nouveau Monde Graphite, Mitsui and Panasonic Energy have entered into a framework agreement to enable the next development steps of NMG’s ore-to-battery-market integrated graphite project in Québec.

The deal includes a multi-year offtake agreement between NMG and Panasonic Energy for a significant portion of NMG’s active anode material.

Also, an investment of US$50 million from Mitsui, Pallinghurst and Investissement Québec will support the next operational milestones for the Matawinie Mine and the Bécancour Battery Material Plant.

“This strategic partnership with NMG will allow us to explore the possibility of establishing an environmentally friendly supply chain in North America through a completely new integrated anode production in Canada,” said Panasonic Energy CEO Kazuo Tadanobu.

“This transformative partnership…is set to provide NMG with a solid commercial foundation for deploying our phase-2 commercial operations,” said Eric Desaulniers, founder and CEO of NMG. “Their participation is a lever to advance our business plan towards establishing what is projected to become North America’s largest fully integrated natural graphite production.”

“NMG is committed to delivering the highest quality anode material, exclusively mined and produced in North America,” said Arne H Frandsen, Chair of NMG. “We will continue to vigorously increase our relevance in the North American market, benefitting from US and Canadian legislation supporting locally produced batteries.”

Source: NMG

Source: Electric Vehicles Magazine

Cirba Solutions and GM extend collaboration on EV battery recycling

Cirba Solutions and GM have extended an existing agreement to recycle battery scrap generated by manufacturing and research at selected GM facilities through 2024. The original agreement dates from 2021, and GM has already recycled more than a million pounds of batteries.

Cirba provides GM with reverse logistics, disassembly and processing to return recycled materials to the market.

The company has six facilities, including two active lithium-ion processing sites. In September 2022, it announced plans to construct a 75,000-square-foot recycling facility in Eloy, Arizona, which is expected to process enough battery material to support 50,000 EVs annually.

Cirba recently received approximately $75 million from the DOE to expand its existing lithium-ion processing facility in Lancaster, Ohio. The company aims to increase its processing capacity by approximately 600% over the next few years, and to open several new facilities in North America.

“Integrating efficient EV battery recycling processes helps lower emissions upstream in the battery supply chain and aligns with our vision for a world with zero crashes, zero emissions and zero congestion,” said Melissa Flaherty, Director of Sustainable EV Battery Ecosystem at GM.

Source: Cirba Solutions

Source: Electric Vehicles Magazine