Raw materials in one end, pallets full of power film capacitors out the other

For companies that produce products used for electric power conversion, EVs represent a huge new market, potentially much bigger than any other existing industry. Those who have realized the potential and invested early are now positioning themselves as leaders in automotive power conversion and beginning to reap the benefits.

TDK develops electronic components focused on fast-growing technology markets including various automotive segments. As one of the major global suppliers to the automotive industry, TDK knows that automakers are looking for repeatability and reliability from their suppliers. For this reason, the company has set out to build fully automated assembly lines for its products.

EVs represent a boom for power electronics parts suppliers. Like many of the applications in the renewable energy sector, e-mobility powertrain applications demand high power with higher voltages and currents along with the highest reliability.

“The solar industry is a huge market for film capacitors,” Eduardo Drehmer, EPCOS Film Capacitor Marketing Director North America, told Charged. “But the installed capacity in electric vehicles will soon surpass that of photovoltaics. So even though the EV market is still in its infant stage, the demand for film power caps is growing fast.”

Strategic automation

In recent years, the number of worldwide EV development projects has become too numerous to count. In order to prepare itself for the growing demand, TDK is redesigning its manufacturing lines for its power film caps.

The company installed its first fully robotic assembly line in early 2018 in Heidenheim, Germany, at the mother factory for film power capacitors for e-mobility applications. Raw materials are fed into machines on one side, and capacitors go onto pallets on the other, all with fully automated process control. The company says this one-of-a-kind system offers the xEV market huge advantages: strong quality control, the ability to more easily expand its capacity with identical lines and processes, and full product traceability.

“Perhaps the biggest advantage of this type of system,” said Drehmer, “is its reproducible quality, especially when it comes to manufacturing customer-specific capacitors in high volumes.”

How it’s made

Inside a large film capacitor there are typically several flat windings. TDK’s automated production process begins with the metallization of a very thin plastic film, only a few micrometers thick. The metallized film is then slit into sections and fed into a winding machine. Such machines must have a high level of mechanical precision to handle the ultra-thin plastic film, and include barcode identification for each winding, allowing full traceability not only of the final product, but of each individual winding used in each capacitor.

“Some of TDK’s key manufacturing technologies involve complex, precision-controlled production processes,” explained Drehmer. “That knowledge was critical in building this system with a high degree of quality control.”

After winding, the thin film windings are compressed into the desired shape. A metal coating is sprayed on the top and bottom to create the conductive contact layer. The windings then undergo annealing – a thermal treatment designed to pre-age them, in a sense, so that when they’re under high-stress operation they don’t change any of their properties anymore.

Throughout this process, each individual internal component is tested to ensure quality control. Thanks to the barcode identification of each component, if a problem arises down the road, the root cause can be identified, traced and addressed.

About a dozen or so of the individual windings – depending on the design of the final product – are connected to busbars and packed into a larger enclosure. Then, resin is added under a vacuum and cured. The final product is thoroughly tested and palletized for delivery.

Customization

It is not uncommon for customers to want something a little different from a standard film power capacitor – slightly different form factors, performance specifications, etc – so each production setup for the customer-specific products will require some element of tailoring.

TDK serves major projects with high volumes, so it works closely with its customers to help design the right EPCOS capacitor for a given application and the required driving profiles. For example, an electric SUV may have to pull a trailer as well as being able to operate reliably at cold temperatures. In contrast, an electric sports car typically used in moderate climatic conditions may have to be designed for striking acceleration and urban stop-and-go traffic at high temperatures. “It’s important to know what sort of performance engineers are looking for,” said Drehmer. “Sometimes they need very high power for a long time, or maybe they need high power just for 20 seconds. Proper thermal management design is also key to ensuring a long life.”

With the first fully automatic assembly line now up and running, TDK says that its strategy is paying off. “We’re happy to say that this investment has been very welcomed by the automotive industry,” said Drehmer. “They want high-quality parts and a repeatable process, and there are very reliable components coming out of this system. We are now ready to reproduce our production lines at our factories for power capacitors around the world and ramp up high-volume production capacity fast according to customer demand.”

What’s a film power capacitor?

Film power capacitors have become an indispensable component in modern EV drives. They are used in the DC link of the inverter to smooth the ripple current. These capacitors must be able to handle high voltages and currents while offering a stable capacitance level over a very long operational lifespan.

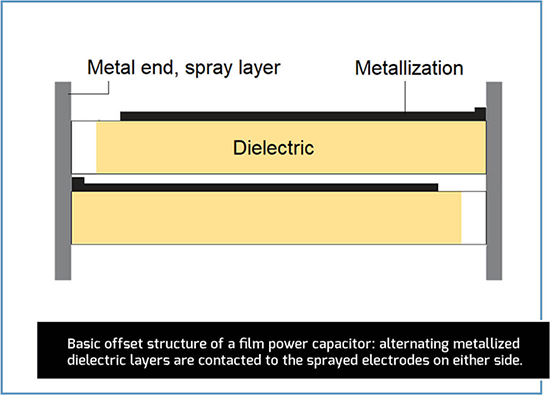

All capacitors store an electrical charge using pairs of conductive layers separated by an insulator, or dielectric. In the case of film capacitors, the dielectric is a plastic film, in most cases polypropylene, that is metallized to form the conductive layer.

The most commonly used method to increase the capacitance at a given voltage rating is to make the insulator very long and roll it up into a cylinder, then to compress the windings until they are flat. By offsetting all the odd layers to one side and the even layers to the other, a massively parallel connection can be made to the external terminal, which dramatically reduces the internal inductance of the capacitor while also increasing its current rating (see figure).

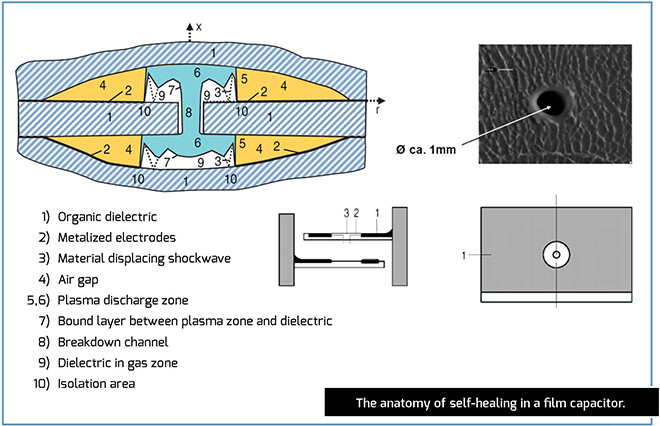

A special feature of film capacitors is their self-healing properties. If a breakdown occurs, the aluminum will evaporate around the breakdown spot and immediately form aluminum oxide, which is an excellent insulator. In a few microseconds the breakdown spot thus becomes highly resistive and is insulated from the rest of the capacitor, ensuring the full functionality of the capacitor after breakdown.

This article appeared in Charged Issue 40 – November/December 2018 – Subscribe now.

Source: Electric Vehicles Magazine