Researchers at Germany’s Fraunhofer Institute for Material

and Beam Technology IWS have developed a new battery cell production process

that coats electrodes with a dry film instead of liquid chemicals. This

simplified process saves energy and eliminates toxic solvents. The Fraunhofer researchers,

with colleagues from Samsung, describe their findings in a new paper, “Overcoming binder

limitations of sheet-type solid-state cathodes using a solvent-free dry-film approach,” published

in Energy Storage Materials.

Maxwell Technologies, now a subsidiary of Tesla, is also working

on a

dry electrode tech that eliminates the need for toxic solvents. Once Tesla and

partner Panasonic get Maxwell’s process up and running, it’s expected to save

loads of money, time and factory space.

Reducing the costs of producing battery cells is a highly

desirable end in itslef, but the Fraunhofer engineers see the potential to

change the global energy storage market. For years, Asian companies have

dominated the battery cell market. German (and US) automakers currently get

most of their cells from Korean and Japanese companies. As the proliferation of

EVs and stationary storage applications increases demand for cells, this is

becoming an increasingly intolerable situation. That’s why, last November, the

German government announced that it would invest a billion euros to support

local battery cell production (as reported by Reuters

via Electrek).

One reason the Asians dominate the cell market is a cost

advantage – the current process for producing cells is very energy-intensive,

and Germany has famously high electricity prices. A lower-cost production

method could change the equation.

“Our dry transfer coating process aims to noticeably reduce

the process costs in electrode coating,” said paper co-author Dr. Benjamin

Schumm. “Manufacturers can eliminate toxic and expensive solvents and save

energy costs during drying. Our technology also facilitates the use of

electrode materials that are difficult or even impossible to process

wet-chemically. For all these reasons, we think that our technology can help to

achieve internationally competitive battery cell production in Germany and

Europe.”

The current wet-chemical process involves mixing the active battery

materials with additives to create a paste, adding expensive organic solvents. Elaborate

precautions are necessary to protect workers and the environment from the toxic

solvents. Once the paste has been applied to thin metal foils, dozens of large

heating elements are used to dry the coated films – this drying procedure is

what racks up the high electricity costs.

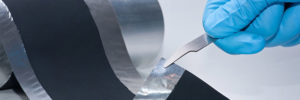

The new film transfer technology eliminates these steps. The

IWS engineers mix their active material with binding polymers, then process

this dry mixture in a rolling mill, where shear forces tear molecular chains

out of the binder polymers. These fibrils join with the electrode particles to

form a web that provides the electrode material with stability. The result is a

flexible dry electrode material layer. In the next step, the rolling mill

laminates the 100-micrometer-thick film onto an aluminum foil to form the finished

electrode.

The Finnish company BroadBit Batteries is working with Fraunhofer to commercialize the new process. The firm has commissioned a pilot plant in its Espoo factory, which will use the dry coating process to produce new types of sodium-ion batteries.

Source: Fraunhofer Institute via Green Car Congress

Source: Electric Vehicles Magazine