Toshiba has developed a new magnetic material with characteristics that could improve motor efficiency at low cost.

Motors account for approximately half of the world’s electric power consumption. Toshiba says its new material boosts energy conversion efficiency when used as the wedges in motors, particularly in medium-to-large induction motors. The material can be installed at minimal cost with no need for design changes.

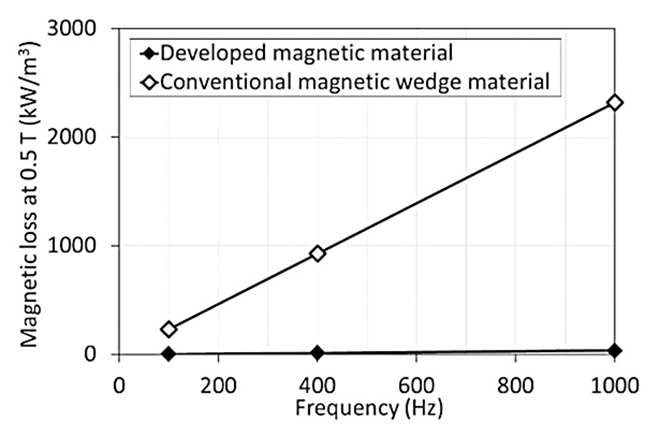

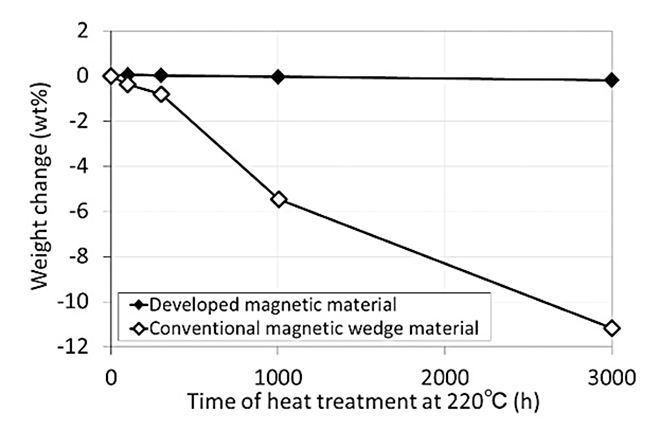

Wedges in motors prevent motor coils from falling out of their slots. They are normally made of non-magnetic material, but magnetic material has been found to guide magnetic flux toward the wedges, improving efficiency. However, the conventional magnetic material used as the wedges consists of spherical magnetic metal particles with insufficient control of the magnetic flux, causing leaks to unwanted directions. The magnetic wedge material itself has high magnetic loss and low heat resistance, making it unsuitable for applications that require high heat resistance.

Through testing in an induction motor in railway rolling stock drive systems, Toshiba observed an efficiency increase of 0.9 percent, an improvement approaching the efficiency of permanent magnet synchronous motors. The material also offers additional heat resistance, making it suitable for applications such as automobiles, robots and industrial and medical equipment.

Source: Toshiba

Source: Electric Vehicles Magazine