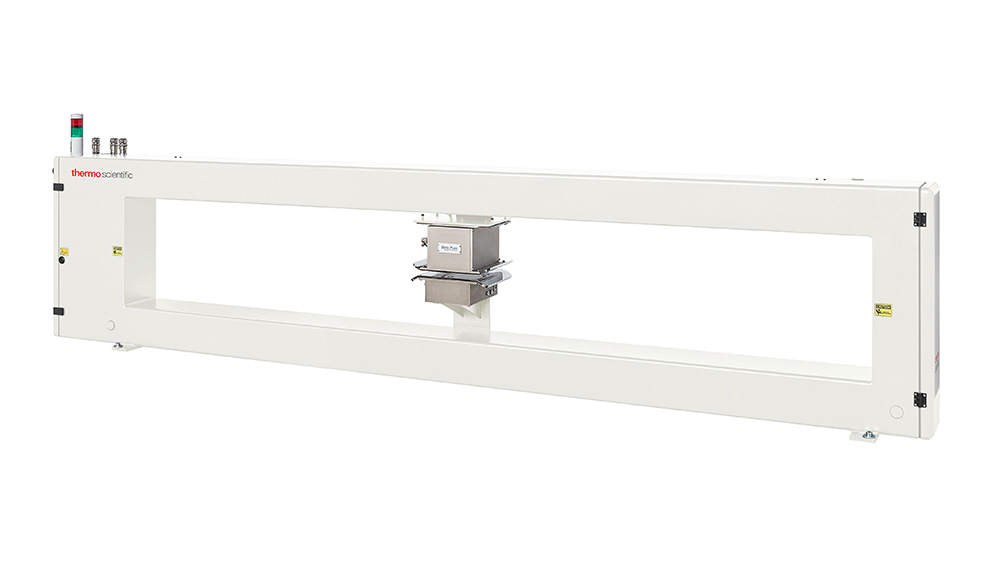

Thermo Fisher Scientific‘s new LInspector in-line measurement and control system is designed to detect defects in lithium-ion battery electrode coatings, electrode calendering and separator films during the manufacturing process, while reducing waste and improving battery quality.

The company says LInspector offers improved basis weight determination, increased scan coverage, measurement precision and sensor accuracy, as well as remote instrument health and status monitoring capabilities. The new system also includes diagnostic display screens and data reporting designed for battery factories.

“Lithium-ion battery manufacturers need confidence that they can detect exceptionally small defects in their products,” said Product Line Manager Tam Nguyen. “LInspector measurement and control system enables battery manufacturers to consistently qualify the thickness and coating uniformity of battery electrodes during the production process at faster speeds and with greater resolution than ever before In addition to exceptional precision and control, the LInspector measurement and control system has intelligent instrument performance monitoring (IPM) with secure data archival and full traceability of product defects.”

Source: Thermo Fisher Scientific

Source: Electric Vehicles Magazine