More positive news in the EV space to start off the week.

Source: Electric Vehicle News

Hyundai Ioniq 5 First Look Review

We get to check out one of only two Ioniq 5s currently in the US.

Source: Electric Vehicle News

Using DC Fast Chargers

A primer on how to use fast-charging stations.

Source: Electric Vehicle News

Elon Musk Says Tesla Will Expedite Service Center Openings

A Tesla owner voiced concerns about the long wait for Tesla Service. Musk replied.

Source: Electric Vehicle News

Macwheel’s 16-inch electric folding bike travels 37 miles per charge at $490, more in New Green Deals

Macwheel’s 16-inch folding e-bike allows you to ride around town then collapse it for easy toting, especially with today’s deal. It’s currently on sale for $490, but also includes an additional $40 gift card making today’s deal the best price that we’ve tracked all-time. Plus, you’ll find discounts on electric lawn mowers and much more below, as well. We also have a wide selection of Tesla, Greenworks, and other e-bike discounts in today’s New Green Deals, so you won’t want to miss that either.

Head below for other New Green Deals that we’ve found today, more on why going electric for your yard tools like the mower on sale is important, and of course Electrek’s best EV buying and leasing deals. Also, check out the new Electrek Tesla Shop for the best deals on Tesla accessories.

The post Macwheel’s 16-inch electric folding bike travels 37 miles per charge at $490, more in New Green Deals appeared first on Electrek.

Source: Charge Forward

Siemens to expand its EVSE manufacturing operations in the US

Electronics giant Siemens plans to expand its US EVSE manufacturing operations.

Siemens expects to manufacture over one million EV chargers for the US market over the next four years. The company will bolster its existing infrastructure offerings with the VersiCharge Level 2 AC series of commercial and residential EV chargers.

Siemens is currently evaluating sites for a new factory. The company plans to identify a location this year and bring a facility online to begin manufacturing AC chargers in the US in early 2022.

The new facility, which will be the company’s third US eMobility hub, will complement Siemens’s existing operations in Wendell, North Carolina, where the company manufactures charging solutions for buses, trucks and heavy-duty EVs. In 2019, Siemens expanded the 272,000-square-foot Wendell facility to manufacture DC fleet EV chargers.

Siemens eMobility solutions include AC and DC chargers ranging from residential chargers to depot chargers to infrastructure systems that power electrified bus lines. The Siemens PlugtoGrid eMobility product portfolio encompasses charging infrastructure hardware, electrical equipment, software and services in the North American EV market.

“As America embraces electrified transportation, we are ensuring the infrastructure is in place to support it,” said Ruth Gratzke, President of Siemens Smart Infrastructure US. “To meet this moment, Siemens is enthusiastically investing in the growth of our US eMobility footprint, [which] will help advance our nation’s climate policy while adding green jobs to the American workforce.”

Source: Siemens

Source: Electric Vehicles Magazine

VW subsidiary MAN announces transition from diesel to all-electric trucks and buses starting in 2024

MAN Truck and Bus, a commercial subsidiary of Volkswagen Group, has announced it will wean its fleet’s dependency on diesel fuel in favor of all-electric powertrains, beginning in 2024. MAN currently offers a few electrified versions of trucks, vans, and buses, but it will focus further on electric commercial vehicles under the pressure of VW. Can it do so quickly enough?

The post VW subsidiary MAN announces transition from diesel to all-electric trucks and buses starting in 2024 appeared first on Electrek.

Source: Charge Forward

Orange EV to deliver 25 electric yard trucks to yard management firm Lazer Spot

Heavy-duty EV builder Orange EV has announced an agreement with Georgia-based Lazer Spot to manufacture and deliver more than 25 electric yard trucks in 2021 and 2022. Lazer Spot, which calls itself the largest yard management firm in the US, has had Orange EV trucks in service for several years with great success.

Yard trucks, also known as terminal trucks, drayage trucks, port tractors, hostlers or (our favorite) yard goats, are used to move trailers and containers around freight terminals, ports and warehouse facilities. They are often cited as an ideal use case for electrification, because they travel short distances within pre-defined areas, offer lower total cost of ownership, and eliminate emissions around port facilities, many of which are major sources of air pollution.

Orange EV is a pioneer in this field—the company introduced its T-Series electric terminal truck in 2014, and now has trucks commercially deployed with over 90 fleets across 19 states, Canada and the Caribbean, which are approaching a collective 1 million hours and 3 million miles of operation.

Based on Orange EV’s data and customer case studies from its first 6 years of deployment, its customers have seen a 75% reduction in downtime versus diesel yard trucks, an 80% reduction in maintenance and repair costs, and savings of 90% in fuel-related costs.

“Orange EV is clearly the industry leader for electric yard truck innovations,” said Lazer Spot CEO Adam Newsome. “They invented and manufactured the first one. Our past successful experience with them allows Lazer Spot to stay ahead and ensure we’re utilizing proven technology and receiving the best-performing and most reliable electric yard trucks available today.”

“While other EV trucks are early-stage, Orange EV has a proven track record, delivering trucks that are both environmentally and economically sustainable, with demonstrated lower total cost of ownership,” said Orange EV CEO Wayne Mathisen.

Source: Orange EV

Source: Electric Vehicles Magazine

Sprint Power to lead project to develop ultra-fast charging 800 V battery systems

Sprint Power is leading a new £9.7-million project aimed at developing ultra-fast charging cells and battery packs for EVs and hybrids. Project CELERITAS is backed by the UK’s Advanced Propulsion Centre (APCUK), as well as a consortium that includes BMW, bp, AMTE Power, Clas-SiC and Eltrium.

Sprint Power will design and develop an 800 V battery platform for EV and hybrid applications, which will integrate system electronics and incorporate multiple charging protocols. Targeting BMW’s future battery specifications and requirements, the battery platform will bring together innovations from each partner. These include rapid charging cell technology from AMTE Power, bp’s thermal management and next-generation EV fluid technology, 1,200 V silicon carbide switching devices from Clas-Sic, Eltrium’s advanced 800 V manufacturing capabilities, and Sprint Power’s own 800 V DC-DC converter and battery management system (BMS) technologies.

The project will deliver two battery systems, one for BEV applications and one for hybrid applications. Each system will include an integrated 800 V to 14 V DC-DC converter, an 800 V BMS, and multiple charging interfaces that will include provision for wireless charging in the future. The platform architecture will be suitable for applications in multiple sectors, from commercial vehicles and energy storage systems to the marine, off-highway and aerospace sectors.

Source: Sprint Power

Source: Electric Vehicles Magazine

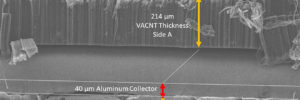

NAWA Technologies begins production of Vertically Aligned Carbon Nanotube material

Energy storage system manufacturer NAWA Technologies has begun manufacturing its Vertically Aligned Carbon Nanotube (VACNT) material. NAWA’s process grows VACNT simultaneously and homogeneously on both sides of a substrate at atmospheric pressure, using a chemical vapor deposition (APCVD) process, in a roll-to-roll manner.

The process has demonstrated the ability to grow up to over 200-micrometer-long VACNT simultaneously on both sides of a 30 cm-wide aluminum foil, and to selectively grow VACNT on the foil—a feature that’s essential for certain electrode designs and for production efficiency.

“We have entered the first exciting industrialization phase, and are on track to rapidly scale up, with mass production set to begin in 2022,” said NAWA Technologies CEO Ulrik Grape. “The potential for our VACNT innovation is massive in energy storage—from bringing about a quantum leap in the performance of electrodes in any battery system, to our next-gen ultracapacitors—and also in reinforced composites. What’s more, we are bringing this unique material to market in an environmentally friendly manner.”

According to the company, this development process is the start of a scale-up in terms of foil width and roll-to-roll productivity. The specific design of this manufacturing system makes it compact compared to conventional coating equipment, resulting in a smaller footprint in a factory environment, while the highly-efficient process means that the production cost of NAWA’s VACNT material may achieve parity with that of a current electrode at future mass production levels.

Source: NAWA Technologies

Source: Electric Vehicles Magazine