Ford F-150 Lightning sales increased so far in 2023, while Mustang Mach-e numbers dropped.

Source: Electric Vehicle News

Privateer Debuts The E-161 Electric Enduro MTB

It’s packing the tried and tested Shimano EP801 motor, as well as e-bike specific suspension from Fox.

Source: Electric Vehicle News

Hyundai Motor Plug-In Car Sales Exceeded 30,000 In June 2023

All-electric car sales almost doubled to 26,000.

Source: Electric Vehicle News

Tesla Cybertruck Will Likely Get Vehicle-To-Vehicle Charging Capability

The possible hint of the feature is hidden in a children’s coloring book.

Source: Electric Vehicle News

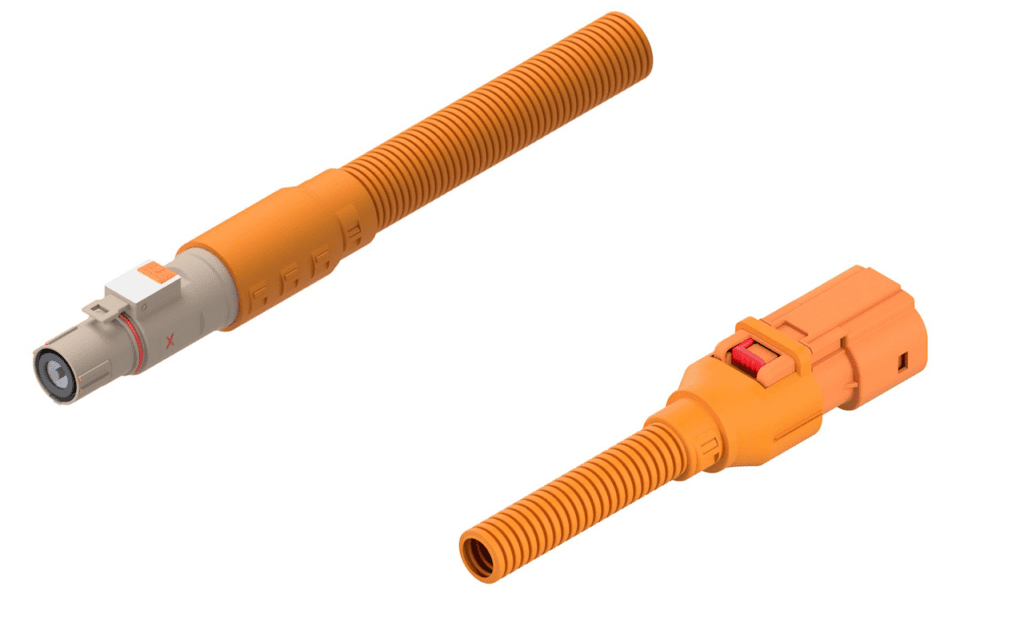

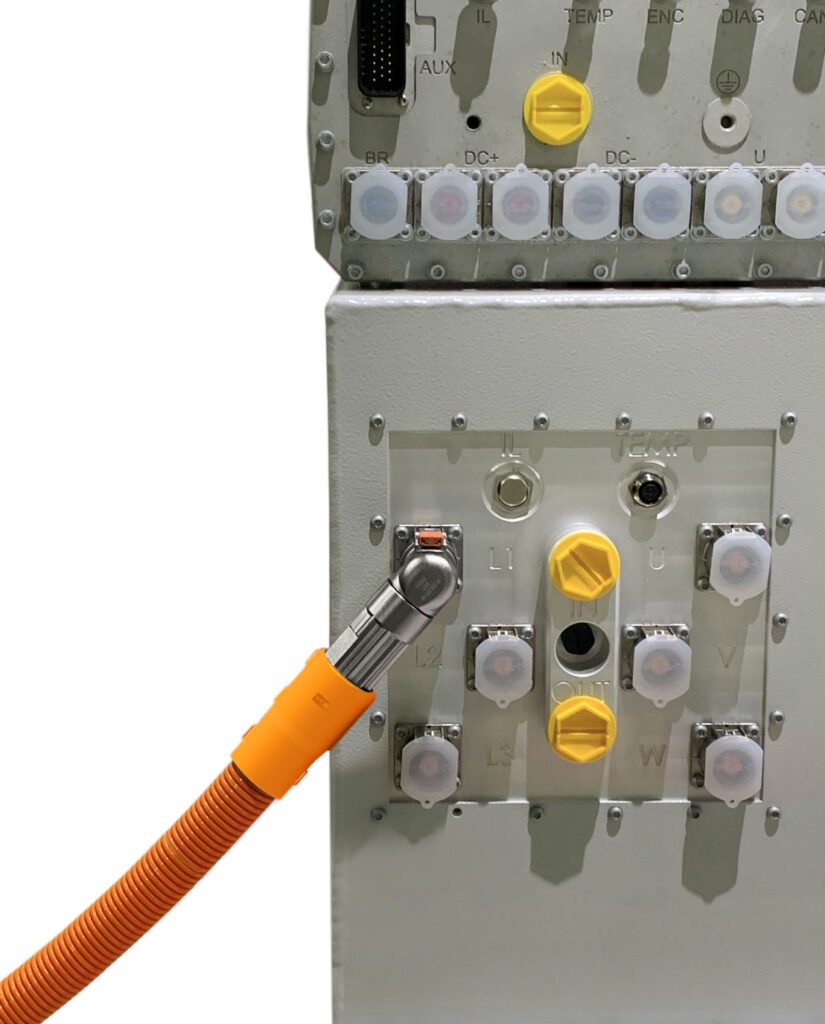

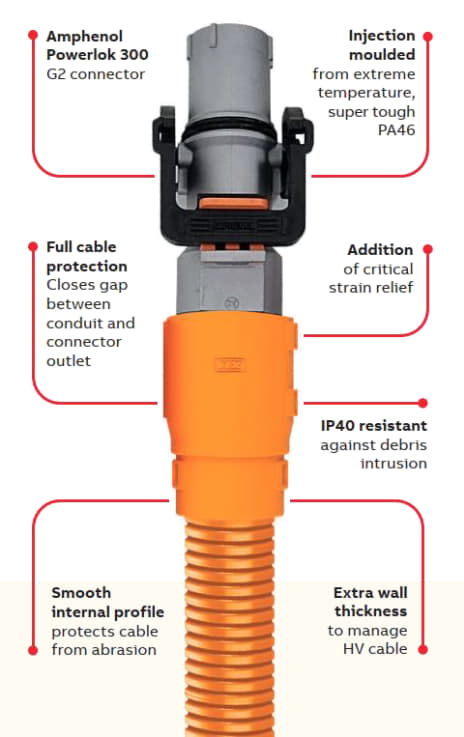

ABB introduces range of hinged high-voltage connector backshells for heavy-duty EVs

Cable-to-connector stability is critical to the operation of any EV. Heavy-duty EV wiring is particularly vulnerable to high engine temperatures, strain, abrasion, vibration, ingress and corrosion. To protect and stabilize these connections, ABB Installation Products has introduced a full range of hinged high-voltage connector backshells.

ABB’s new Harnessflex EVO Connector Interfaces are part of a complete cable protection system designed to meet or exceed industry standards, protect critical wiring, and improve performance and reliability in high-voltage applications.

The Electric Vehicle Orange color of ABB’s Harnessflex EVO Connector Interfaces indicates high-voltage wiring and components. The interfaces are designed to deliver cable-to-connector strain relief with high mechanical performance, and to prevent debris intrusion.

“ABB is working with vehicle makers, transportation providers and OEMs to integrate robust electrical wiring solutions that meet evolving requirements, while delivering safer and reliable performance,” said ABB Installation Products EVP Andrea Castella. “Harnessflex EVO Connector Interfaces offset the need for expensive, bulky cable clamps in high-voltage applications, and expand ABB’s electrification solutions for a broad range of demanding areas of transportation, from construction and agriculture to trucks, buses and trains.”

“ABB’s first-of-its-kind Harnessflex EVO Connector Interfaces reduce cable movement and form tighter junction joints for safer and more secure high-voltage connections in electric ancillaries, DC/DC converters, onboard chargers, high-voltage battery packs, hybrid systems, hydrogen fuel cell vehicles, and dynamic and static power systems,” notes Nathan Cook, Global Business Development Manager for Cable Management Products.

Source: ABB Installation Products

Source: Electric Vehicles Magazine

Controlled Thermal Resources selects Aquatech for $1-billion Lithium Hydroxide Facility in California

US lithium-extraction company Controlled Thermal Resources (CTR) has selected US lithium processor Aquatech to deliver the engineering and process plants for the conversion of lithium chloride intermediate product to battery-grade lithium hydroxide monohydrate at CTR’s Stage 1 Lithium Hydroxide Facility. Construction is expected to start in 2024 and production in 2025.

CTR says the new plant will be a fully integrated renewable power and lithium extraction facility producing “green” battery-grade lithium hydroxide product from its geothermal brine resource at the Salton Sea in California’s Imperial Valley. Expected annual production is 27,557 tons of battery-grade lithium hydroxide monohydrate, sufficient to make batteries to power around 415,000 EVs.

The production facility will comprise multiple process plants that integrate membrane, evaporation and crystallization technology and use lithium chloride eluate recovered by means of direct lithium extraction from the geothermal lithium brine resource.

CTR’s entire Hell’s Kitchen project has an estimated projected yearly production capacity of 1,100 MW of baseload renewable power and 300,000 metric tons of lithium carbonate equivalent products, enough to support production of more than 5 million EVs.

Source: CTR

Source: Electric Vehicles Magazine

Introducing the Charged Virtual Conference on EV Infrastructure

Charged Electric Vehicles Magazine presents a free online event focused on EV infrastructure, December 4-6, 2023, featuring:

- Live webinars

- On-demand recorded videos

- Whitepapers

- Interactive Q&As

Who will attend?

The conference audience is a quickly growing segment of global professionals tasked with planning and deploying large EV fleets and charging projects. The discussions will focus on anticipating and overcoming EV infrastructure challenges.

Learn more at https://www.chargedcon.com/infrastructure-conference

Call for Speakers

Do you have practical expertise in planning and deploying EV fleets and infrastructure? Share it with the EV industry at our Virtual Conference. Suggest a topic to learn more about presenting a live or pre-recorded webcast.

Sponsorship Opportunities

Learn more about our lead generation programs and sponsorship opportunities here.

Source: Electric Vehicles Magazine

Li-S Energy claims to boost energy density by 45% with new 20-layer lithium-sulfur battery

Li-S Energy has revealed its first 20-layer battery cells using its third-generation semi-solid-state lithium-sulfur (GEN3 Li-S) technology.

GEN3 Li-S 20-layer battery cells use a patented low-flammability electrolyte Li-nanomesh technology and Boron Nitride Nanotubes (BNNTs) to prevent dendrite formation. Compared to the company’s second-generation lithium-sulfur cells, the new cells offer greater energy density and more safety, due to a lower-porosity cathode material, optimized cathode material composition and low-flammability electrolyte.

GEN3 cells currently demonstrate specific energy of 400 Wh/kg and energy density of 540 Wh/l. Li-S Energy says this is roughly double the energy density of Li-ion cells.

“Based on inquiries to date we anticipate this will be of significant commercial interest to high-value partners in sectors such as drones and eAviation,” the company said. “In addition to the GEN3 semi-solid-state Li-S cells, we continue to progress our R&D on full solid-state electrolytes in a co-funded project within the ARC Research Hub for Safe and Reliable Energy at Deakin, where we jointly aim to create a full-solid-state Li-S battery.”

Source: Li-S Energy

Source: Electric Vehicles Magazine

Aptera Meets Pininfarina's Wind Tunnel For Validation Phase

Carlsbad, California-based EV startup Aptera Motors has recently been testing its vehicle’s aerodynamics with Pininfarina’s wind tunnel.

Source: Electric Vehicle News

FJ Dynamics MP500 Portable Power Station — CleanTechnica Tested

Smartphones have changed the world of computing in many ways. When some of us were kids, a computer that could only do a few basic things took up a lot of surface area on a desk. If you wanted something capable of playing the latest 3D games where everything resembled the endlessly upcoming Cybertruck, you’d […]

Source: CleanTechnica Car Reviews RSS Feed